The story of humanity’s first steps on another celestial body is inextricably linked with a machine of almost mythical proportions: the Saturn V rocket. It wasn’t merely a vehicle; it was a colossal testament to ambition, ingenuity, and the relentless pursuit of a dream that once seemed confined to the pages of science fiction. This behemoth of engineering, standing taller than the Statue of Liberty, was the key that unlocked the Moon for humankind, a feat that continues to echo through the corridors of history.

Why build such a titan? The answer lies in the fervent atmosphere of the mid-20th century. The Cold War was raging, and space became a new frontier for demonstrating technological supremacy. After the Soviet Union’s early successes with Sputnik and Yuri Gagarin, the United States felt an urgent need to catch up and surpass its rival. President John F. Kennedy’s bold declaration in 1961 – to land a man on the Moon and return him safely to Earth before the decade was out – set an audacious goal that demanded an equally audacious machine.

The task of developing this lunar launch vehicle largely fell to a team at NASA’s Marshall Space Flight Center, led by Dr. Wernher von Braun. While his background prior to working for the US was complex, von Braun was undeniably a brilliant rocket engineer. His team, comprised of many German specialists and a growing number of American engineers, possessed the vision and the technical expertise to transform Kennedy’s challenge into a tangible reality. They knew that reaching the Moon would require a rocket with power far exceeding anything built before.

Towering Power and Colossal Scale

To truly grasp the Saturn V’s essence, one must first appreciate its sheer size and brute force. Fully assembled and fueled, it stood a staggering 363 feet (110.6 meters) tall – imagine a 36-story building thundering into the sky. Its launch weight was over 6.2 million pounds (2.8 million kilograms), the vast majority of which was propellant. This wasn’t just big; it was a skyscraper designed to fly.

The heart of its power lay in its engines. The first stage alone boasted five F-1 engines, the most powerful single-chamber liquid-fueled rocket engines ever developed. Each F-1 engine generated a phenomenal 1.5 million pounds of thrust. Collectively, these five giants unleashed over 7.5 million pounds of thrust at liftoff, an energy output equivalent to many dozens of large passenger jets taking off simultaneously. The ground shook for miles around, and the roar was an elemental force, a physical sensation as much as a sound.

The Saturn V remains the most powerful rocket ever successfully brought to operational status. Its combined first-stage thrust of over 7.5 million pounds was essential for lifting the heavy Apollo spacecraft and its crew out of Earth’s gravity. This raw power was a critical ingredient in the recipe for reaching the Moon, a benchmark for heavy-lift launch vehicles.

A Symphony in Three Stages

The Saturn V was not a single, monolithic structure but a carefully orchestrated sequence of three distinct stages, each with its own role, its own engines, and its own fuel. This staging was crucial; shedding spent weight as the rocket ascended was the only way to achieve the velocities needed for lunar missions. Each stage would fire, expend its fuel, and then separate, making the remaining vehicle lighter and more efficient.

The First Stage: S-IC

The S-IC, built by Boeing, was the mighty workhorse that did the initial heavy lifting. This stage, 138 feet long and 33 feet in diameter, housed the five F-1 engines. It carried approximately 4.4 million pounds of propellant: highly refined kerosene (RP-1) as fuel and liquid oxygen (LOX) as the oxidizer. For about two and a half minutes after ignition, these engines would burn ferociously, consuming propellant at an astonishing rate of nearly 13 tons per second. By the time the S-IC had done its job, it had propelled the rest of the Saturn V to an altitude of around 42 miles (68 kilometers) and a speed of over 6,000 miles per hour, pushing it through the densest part of Earth’s atmosphere.

The Second Stage: S-II

Once the S-IC’s fuel was exhausted, it separated and fell back to Earth, typically into the Atlantic Ocean. Moments later, the second stage, the S-II, ignited. Built by North American Aviation, the S-II was powered by five J-2 engines, which were also formidable but used a different, more efficient propellant combination: liquid hydrogen (LH2) and liquid oxygen (LOX). Liquid hydrogen, while offering higher performance (a higher specific impulse), presented significant engineering challenges due to its extremely low temperature (minus 423 degrees Fahrenheit or minus 253 degrees Celsius) and its low density, requiring very large, exceptionally well-insulated tanks. The S-II, measuring 81.5 feet long, burned for about six minutes, pushing the remaining vehicle to an altitude of nearly 109 miles (175 kilometers) and a speed close to orbital velocity, around 15,600 mph.

The Third Stage: S-IVB

The Douglas Aircraft Company manufactured the S-IVB, the third and most versatile stage. It was powered by a single J-2 engine, the same type used on the second stage. The S-IVB had a dual role, a critical piece of ingenuity in the mission architecture. First, after the S-II separated, its J-2 engine would fire for about two and a half minutes to insert the Apollo spacecraft into a low Earth orbit. The crew and mission control would then perform extensive systems checks to ensure everything was ready for the next crucial step. Later, after one or two orbits, the S-IVB’s J-2 engine would be reignited for the critical Trans-Lunar Injection (TLI) burn. This burn, lasting around six minutes, accelerated the Apollo spacecraft out of Earth orbit and onto a trajectory towards the Moon, reaching a speed of nearly 25,000 mph, the escape velocity needed to break free from Earth’s gravitational pull.

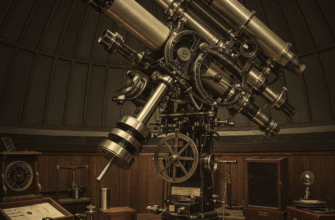

The Instrument Unit: The Brain

Perched atop the S-IVB stage was the Instrument Unit (IU), a three-foot-high, 21.7-foot-diameter ring. This unassuming component was the nerve center, the sophisticated “brain,” of the Saturn V. Built by IBM, the IU contained the guidance, navigation, and control systems that kept the massive rocket on its precise course. It housed gyroscopes, accelerometers, a digital computer (one of the pioneering uses of integrated circuits in such a critical role), and other vital electronics to monitor and adjust the rocket’s flight path, orchestrate stage separations, and control engine firings. Without the IU’s unwavering accuracy and rapid calculations, the lunar missions, which required pinpoint navigation over hundreds of thousands of miles, would have been simply impossible.

Carrying Precious Cargo

The entire purpose of this multi-stage behemoth, with all its power and complexity, was to carry its payload towards the Moon. For the Apollo missions, this payload consisted of the Apollo spacecraft itself, which was a sophisticated assembly of three main components, each essential for the mission’s success:

- The Command Module (CM): The conical crew cabin, a relatively small space, where the three astronauts lived and worked during the multi-day journey to and from the Moon. It was also the only part of the Apollo spacecraft designed to withstand the fiery reentry through Earth’s atmosphere and return the crew safely via parachute landing in the ocean.

- The Service Module (SM): Attached directly to the base of the CM, this cylindrical section contained the main propulsion system (the Service Propulsion System, or SPS engine) for major course corrections, for entering lunar orbit, and for leaving lunar orbit to return to Earth. It also housed vital oxygen tanks, water, fuel cells for electrical power, and other life support systems.

- The Lunar Module (LM): Tucked away beneath the SM inside a conical adapter fairing during launch and the outbound journey, this spidery, almost fragile-looking craft was designed to carry two astronauts from lunar orbit down to the Moon’s surface and then launch them back up to rendezvous and dock with the orbiting Command Module. It was the first true spacecraft, designed to operate only in the vacuum of space.

Later, modified Saturn V rockets, specifically a two-stage version called the Saturn INT-21, were also used to launch the Skylab space station, America’s first experimental space station, in 1973. This demonstrated the rocket’s versatility beyond just lunar missions and its capability to lift extremely heavy payloads into Earth orbit.

Assembly and the Roar of Launch

The sheer scale of the Saturn V necessitated equally massive infrastructure. At NASA’s Kennedy Space Center in Florida, the Vehicle Assembly Building (VAB) was constructed specifically for this purpose. This iconic structure, one of the largest buildings in the world by volume, was where the three stages of the Saturn V, along with the Apollo spacecraft, were meticulously stacked and assembled vertically on a mobile launch platform. Once fully assembled, the entire 363-foot tall rocket, platform and all, weighing over 12 million pounds combined, was moved by a gargantuan machine called the Crawler-Transporter. This tracked vehicle, itself an engineering marvel weighing 6 million pounds, moved at a stately one mile per hour on the 3.5-mile journey along a specially built “crawlerway” to one of the two launch pads at Launch Complex 39.

Launch day was an event of unparalleled spectacle and raw power. As the final seconds of the countdown ticked away, millions of gallons of water would flood the flame trench beneath the launch pad to suppress the intense acoustic energy and heat, protecting the rocket and the pad itself. Ignition of the five F-1 engines sent shockwaves through the ground, felt by observers miles away. The sound was not just heard; it was a visceral, chest-thumping experience, a deep rumble that vibrated through your very bones. Slowly, majestically, as if defying its own immense weight, the Saturn V would rise, clearing the launch tower and beginning its ascent, a pillar of fire and smoke against the Florida sky, carrying the hopes of a nation and the dreams of humanity.

A Legacy of Success

Between November 1967 (Apollo 4, an uncrewed test) and May 1973 (Skylab 1), thirteen Saturn V rockets were launched. Remarkably, every single one of these launches was successful in achieving its primary mission objectives. From the uncrewed test flights like Apollo 4 and Apollo 6, which validated the rocket’s design, to the historic Apollo 8 mission that first took humans around the Moon, to the iconic Apollo 11 landing, and through to the final Apollo 17 lunar mission, the Saturn V performed flawlessly for its crewed flights. This perfect record for human spaceflight missions is a testament to the meticulous design, rigorous testing, and dedicated work of hundreds of thousands of engineers, scientists, and technicians across the country.

It enabled six crewed lunar landings, allowing twelve astronauts to walk on the Moon, conduct experiments, and collect samples. Beyond the Moon landings, it launched Skylab, which hosted three crews for progressively longer missions and provided invaluable data on long-duration spaceflight and Earth observation. The technological innovations spurred by the Saturn V program had far-reaching impacts in fields like materials science (new alloys and insulators), computer technology (miniaturization and software reliability), and systems management (coordinating vast, complex projects).

The End of a Giant’s Reign

Despite its unparalleled success, the era of the Saturn V was relatively short-lived. The immense cost of each launch – estimated to be around $185 million in 1970s dollars (well over a billion in today’s money) – became difficult to justify as national priorities shifted away from the intense pace and singular focus of the Apollo program. The Cold War space race had largely been won, and domestic issues gained more attention. The last Saturn V launch was for Skylab in May 1973. After that, the remaining rockets and components, including three flight-ready Saturn Vs, were either used for spares for Skylab or designated for museum display, as funding for further Apollo missions (Apollo 18, 19, and 20 had been planned) was cut.

The cancellation of further Apollo missions meant that the mighty launch vehicle, designed specifically for deep space exploration, no longer had a primary mission. The Space Shuttle program, with its focus on reusable spacecraft for Earth orbit operations, became NASA’s next major human spaceflight endeavor. While the Shuttle was a marvel in its own right and achieved many great things, it did not possess the heavy-lift capability to send humans and large payloads beyond low Earth orbit in the same way the Saturn V could.

A Lasting Symbol of What’s Possible

Today, the remaining Saturn V rockets stand as silent, awe-inspiring monuments in museums across the United States, including the Kennedy Space Center Visitor Complex in Florida, the Johnson Space Center in Houston, Texas, and the U.S. Space & Rocket Center in Huntsville, Alabama. They serve as powerful, tangible reminders of a time when a nation dared to dream big and mobilized its resources to achieve the seemingly impossible. The Saturn V was more than just a machine; it was the embodiment of human aspiration, a symbol of what can be accomplished when focused effort, brilliant engineering, and bold vision come together on a grand scale.

Its legacy continues to inspire new generations of engineers, scientists, and explorers. As humanity once again sets its sights on the Moon with programs like Artemis, and eventually Mars, the lessons learned from the design, construction, and operation of the Saturn V provide invaluable knowledge and a towering standard. It remains the benchmark against which all super heavy-lift rockets are measured, a true engineering marvel that literally took humans to the Moon and, in doing so, expanded our horizons forever, proving that even the most distant dreams can be reached.