The quest to gaze deeper into the cosmos has always been intrinsically linked to the evolution of the telescope’s primary light-gathering element. While early refracting telescopes, with their lenses, opened new windows to the universe, they suffered from chromatic aberration, a rainbow-like distortion that plagued larger instruments. The solution lay in reflection, not refraction. Sir Isaac Newton, in 1668, famously demonstrated a practical reflecting telescope, using a mirror crafted from speculum metal, an alloy typically composed of copper and tin. This marked the genesis of a new era in astronomical observation, but the path of mirror making was fraught with immense challenges.

The Era of Speculum: Promise and Peril

Speculum metal, while capable of taking a high polish, was notoriously difficult to work with. It was brittle, prone to cracking during casting or cooling, and tarnished relatively quickly, requiring frequent and laborious re-polishing. Each re-polishing session risked altering the painstakingly achieved optical figure. Early opticians like John Hadley, who presented an improved Newtonian reflector to the Royal Society in 1721, and James Short, a Scottish optician renowned in the mid-18th century for his exquisite speculum mirrors, pushed the boundaries of what was possible. Short, in particular, produced hundreds of telescopes, meticulously figuring his mirrors to achieve remarkable performance for their time. Another notable contributor was John Mudge, who published on techniques for creating parabolic surfaces, essential for sharp images.

The process involved casting a blank, often a hazardous affair with molten metal, then grinding it to the approximate curve using progressively finer abrasives. Polishing, the final and most critical stage, was done with a tool covered in pitch, charged with jeweler’s rouge (iron oxide). Achieving the correct parabolic shape, rather than a simpler spherical one, demanded immense skill, patience, and a keen sense of touch, as precise testing methods were still in their infancy.

Titans of Metal: Herschel and Rosse

The ambition to build ever-larger telescopes drove innovation in speculum mirror making. William Herschel, discoverer of Uranus, became a master mirror maker out of necessity. Frustrated by the quality and cost of available mirrors, he embarked on a relentless campaign of casting and polishing, reportedly making over four hundred speculum mirrors throughout his career. His famous 40-foot telescope, completed in 1789, boasted a primary mirror nearly 48 inches in diameter. Herschel developed techniques for large-scale grinding and polishing, often employing teams of workers for the sheer physical effort involved. He understood the need for multiple mirrors, so one could be in use while another was being re-polished.

The zenith of speculum mirror technology was arguably reached with William Parsons, the 3rd Earl of Rosse. In the 1840s, at Parsonstown, Ireland, he constructed the “Leviathan,” a telescope with a staggering 72-inch (1.8-meter) speculum mirror. The challenges were immense: casting a three-ton disc of brittle metal without it shattering upon cooling was a monumental feat of engineering. Lord Rosse developed innovative casting techniques, including a mould with a permeable base to allow gases to escape, and sophisticated annealing ovens. Grinding and polishing such a behemoth required steam-powered machinery, a significant departure from the manual methods of earlier opticians. The Leviathan, despite its unwieldiness and the Irish climate, made significant astronomical discoveries, including the spiral structure of some nebulae.

The Shift to Silvered Glass: A Brighter Reflection

Despite the triumphs of Herschel and Rosse, the limitations of speculum metal were becoming increasingly apparent. The low reflectivity (around 60-65% even when freshly polished), the immense weight, and the constant need for re-polishing spurred the search for better materials. The breakthrough came in the mid-19th century with the advent of chemically silvered glass mirrors.

Independently, Léon Foucault in France and Justus von Liebig in Germany developed practical methods for depositing a thin, highly reflective layer of silver onto a glass substrate around 1856-1857. Glass offered numerous advantages: it was lighter than speculum, more dimensionally stable with temperature changes (though early plate glass still had issues), and, crucially, if the silver tarnished, it could be chemically stripped and re-applied without affecting the underlying precision optical figure of the glass. This was a game-changer.

Foucault’s Enduring Legacy: Testing and Figuring

Foucault’s contribution extended beyond just the silvering process. In 1858, he introduced the Foucault knife-edge test, a deceptively simple yet incredibly sensitive method for evaluating the surface accuracy of a concave mirror. This test allowed opticians to “see” imperfections on the mirror’s surface, deviations from the desired parabolic shape as small as a fraction of the wavelength of light. For the first time, mirror makers had a precise, quantitative way to guide their polishing efforts, transforming mirror figuring from a somewhat occult art into a more scientific process. This enabled the creation of far more accurate mirror surfaces than had previously been feasible.

Léon Foucault’s dual innovations—the silver-on-glass mirror (1857) and the knife-edge test (1858)—revolutionized telescope mirror fabrication. These advancements provided a pathway to lighter, more reflective, and, critically, far more accurately figured mirrors. His testing method, in particular, gave opticians unprecedented control over the shaping process, directly enabling the construction of the large, high-performance telescopes that would define 20th-century astronomy.

Perfecting the Art and Science: The Late 19th and Early 20th Centuries

The adoption of silvered glass mirrors spurred further advancements. Glass manufacturers, like Schott in Germany, began producing larger, higher-quality glass blanks specifically for astronomical purposes. The focus shifted to refining grinding, polishing, and testing techniques to achieve ever-greater precision on these new substrates. Figures like John Brashear in America became renowned for their exceptional skill in producing mirrors and lenses. Brashear, along with his son-in-law and collaborator John Alfred McDowell, and later George Willis Ritchey at the Mount Wilson Observatory, set new standards for optical quality.

Ritchey, in particular, was instrumental in developing techniques for figuring large mirrors, including the 60-inch and 100-inch reflectors at Mount Wilson. He emphasized meticulous temperature control during polishing and testing, recognizing the impact of thermal expansion on the glass. The development of testing towers and the use of sophisticated null tests, often extensions or variations of Foucault’s method, became standard practice. Around this time, the importance of low-expansion materials also became evident, leading to the development and adoption of Pyrex (borosilicate glass) by Corning Glass Works in the 1930s for the 200-inch Hale Telescope mirror on Palomar Mountain. Pyrex’s significantly lower coefficient of thermal expansion meant that the mirror’s figure was less distorted by temperature changes, a critical factor for large optics.

Pushing the Envelope: Modern Mirror Making Techniques

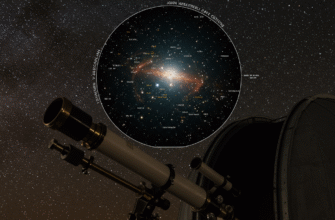

The quest for larger and more perfect mirrors has continued into the modern era, bringing forth a host of sophisticated techniques. While the fundamental principles of grinding and polishing remain, the execution has become highly advanced.

One significant innovation is spin-casting, pioneered by Roger Angel at the University of Arizona’s Steward Observatory Mirror Lab. Large, relatively thin meniscus mirrors are cast from molten borosilicate glass in a rotating furnace. The centrifugal force naturally pushes the glass up the sides of the mold, forming an approximately parabolic curve, greatly reducing the amount of glass needed and the subsequent grinding time. These mirrors often feature a lightweight honeycomb structure on the back to reduce mass while maintaining stiffness.

Polishing techniques have also evolved. While traditional pitch laps are still used, computer-controlled polishing machines can now execute highly precise figuring paths. For the finest corrections, techniques like ion beam figuring (where a beam of ions sputters away material atom by atom) and stressed lap polishing (where the lap’s shape is actively controlled) are employed to achieve nanometer-level accuracy.

Material science has also advanced beyond Pyrex. Materials like Zerodur (a glass-ceramic by Schott) and ULE (Ultra-Low Expansion glass by Corning) have near-zero coefficients of thermal expansion over a wide range of temperatures, making them ideal for space telescopes and large ground-based observatories where thermal stability is paramount. The development of active and adaptive optics systems, which can correct for atmospheric distortions and even minor imperfections or flexures in the mirror itself, has further driven the need for exquisitely made, though sometimes more flexible, primary mirrors.

The journey of telescope mirror making, from Newton’s small speculum disc to the giant, precisely controlled segments of today’s Extremely Large Telescopes, is a testament to centuries of human ingenuity, perseverance, and the unending desire to explore the universe.